Application of OEM Peristaltic Pump in Small Fermentation Tank Fermentation Experiment in Laboratory

It is generally considered that: below 500L is the fermentation tank of laboratory scale, and above 500L is the fermentation tank of production scale.

Small fermentation tank fermentation in the laboratory is the prototype and basis of industrial fermentation tank fermentation, which provides data information for production scale fermentation tank operation, including seed validation, medium formula selection, process parameter optimization, etc. Therefore, it is the only way to put the small fermentation tank into industrial production in the future!

The fermentation tank of laboratory scale is generally equipped with four-way peristaltic pump for each reaction vessel. Generally, the OEM products of the fixed speed peristaltic pump are selected. The control system controls the addition amount by controlling the start and stop time of the peristaltic pump.

Two circuits of peristaltic pump add acid and alkali: the control system controls the PH value of the reaction environment to the set target value through PH value monitoring and closed-loop control of adding acid or alkali.

One way peristaltic pump adds defoaming agent: the control system controls the foam amount in the reaction environment to the set target value through foam monitoring and closed-loop control of adding defoaming agent.

The other way of peristaltic pump adds culture medium: the control system controls the nutrient level of the reaction environment to the set target value through nutrient level monitoring and closed-loop control of adding nutrient reagents.

During the fermentation test in the fermentation tank, the fermentation medium is used for the growth, reproduction and synthesis of culture. It not only enables the seeds to grow quickly after inoculation to reach a certain mycelial concentration, but also enables the good thalli to quickly synthesize the required products. Therefore, it is required that the composition of fermentation medium should be rich and complete, the carbon and nitrogen sources should pay attention to the matching of quick and slow nutrients, and use less quick nutrients and more late nutrients; Appropriate carbon-nitrogen ratio shall be considered, and buffer shall be added to stabilize pH value; In addition, there are growth factors required for cell growth and elements, precursors and accelerants required for product synthesis. In addition to the elements and compounds necessary for cell growth, there are also specific elements, precursors and accelerants required for the product. However, if the concentration of total carbon sources, nitrogen sources, phosphorus sources, etc. required for growth and biosynthesis products is too high, or if the optimal conditions required for growth and synthesis are different, it can be considered that the culture medium can be supplemented by batches.

While defoaming agent and other reagents are also indispensable, because during the fermentation experiment, the microorganism must produce metabolites, which will cause the change of pH in the bacterial liquid, and with the progress of fermentation, a large number of bubbles will be generated, so that the dissolved oxygen of the bacterial liquid decreases, resulting in the failure of normal growth and reproduction of the bacteria. At this time, acid and alkali are required to adjust its pH value, and antifoaming agent is used to eliminate a large number of bubbles to achieve the most suitable growth environment.

Related Products >

-

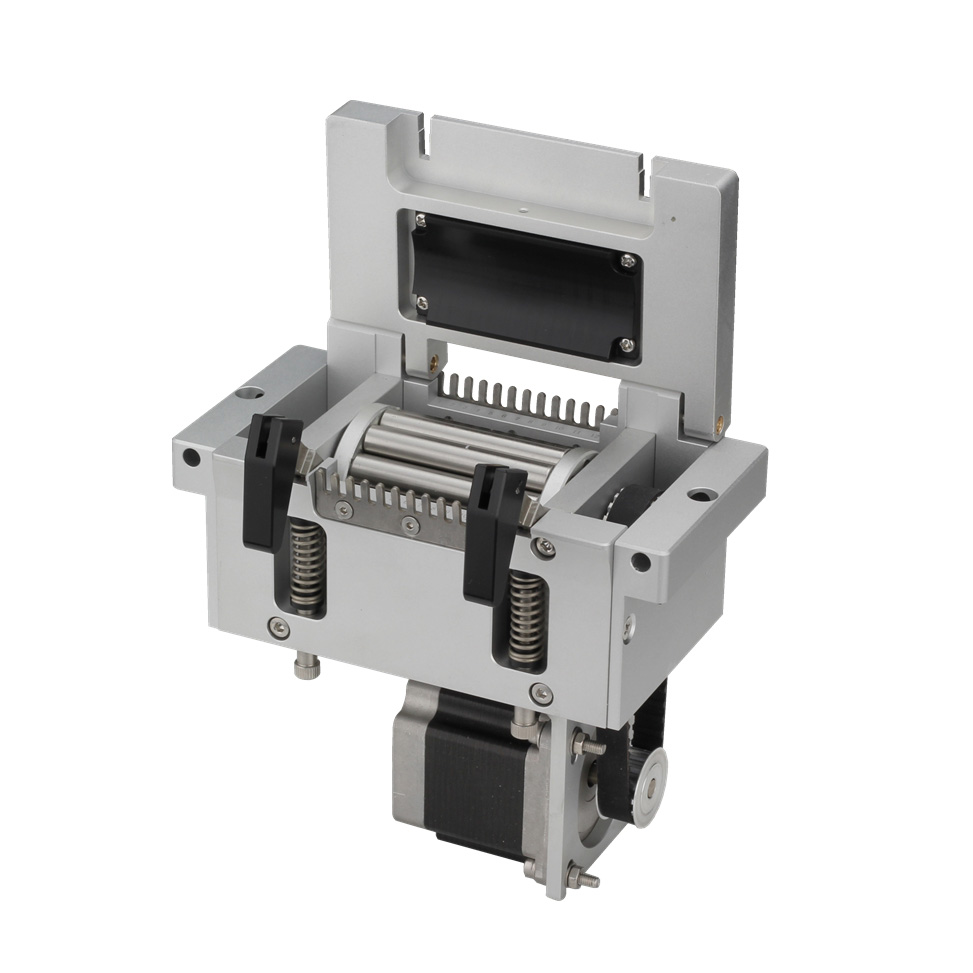

OEM-YG1212 Cap-pressing peri

The 12-channel integrated pressure block ,replace tubing easily and adjust flow conveniently. Solved the problem of excessive error between the channels of the

View product

-

WT600D High-flow constant-fe

Speed : 0.1-600 rpm,reversibleSpeed resolution : 0.1rpm(<100rpm), 1rpm(≥100rpm)Applicable pump heads : YZ1513、YZ2513、DMD1513、KZ25、YZ3513Flow rates : 0.0

View product

-

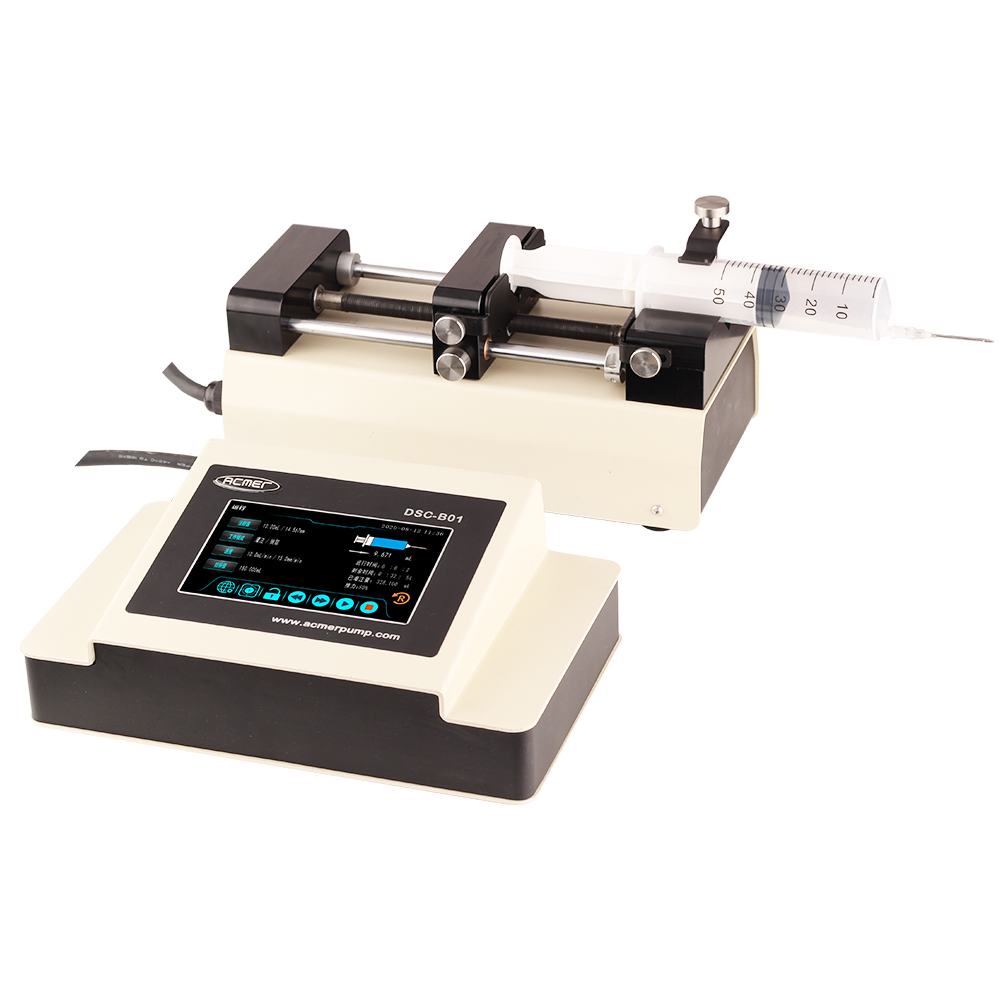

DSC-B01H2+W150-B01H2 High pr

Working Mode Infusion, Withdraw, Infusion / Withdraw, Withdraw / Infusion, Multipleinjection, Continuous No. of Syringes 1

View product

-

DSC-B01/W150-B01 Microfluidi

Working Mode Infusion, Withdraw, Infusion / Withdraw, Withdraw / Infusion, Multipleinjection, Continuous No. of Syringes 1

View product