Application of Peristaltic Pump in Continuous Emission Monitoring System of Flue Gas

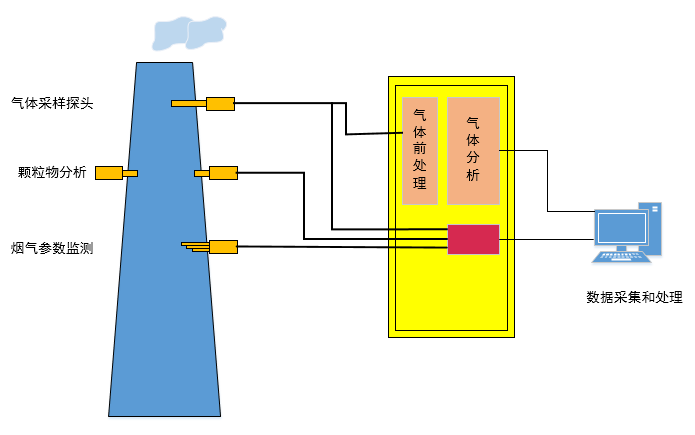

Automatic flue gas monitoring system refers to the device that continuously monitors the concentration and total emission of gaseous pollutants and particulate matter emitted from the air pollution source and transmits the information to the competent department in real time.

CEMS consists of gaseous pollutant (SO2, NOX) monitoring subsystem, particulate matter (dust) monitoring subsystem, flue gas parameter measurement subsystem, data acquisition and processing subsystem, data communication system, etc. Through field sampling, measure the pollutant concentration in the flue gas, measure the temperature, pressure, flow rate, humidity, oxygen content and other parameters of the flue gas, and calculate the emission rate and amount of flue gas pollutants.

Typical requirements

Before the flue gas enters the gas analyzer, the automatic flue gas monitoring system needs to condense the flue gas for gas-water separation and discharge the condensed water out of the system.

This prevents corrosion of the gas analyzer and multiple components due to excessive flue gas humidity. Gas monitoring needs to strictly ensure the tightness of the monitoring system. Therefore, the condensate discharge system is required to have good tightness to prevent external air from entering the condenser through the drainage system and affecting the sample gas composition.

The chemical composition of condensate is complex and corrosive to some extent. When the sample gas filtration effect is poor in the early stage, the condensate will also contain solid particles. Therefore, the condensate discharge system shall have good anti-corrosion performance and be applicable to abrasive fluid.

Value of application

The peristaltic pump has good sealing performance, wide flow range, strong self-priming capacity and stability. When transferring fluid, the fluid only contacts with the hose. The corrosion resistant hose can be selected to transfer various corrosive fluids, and the abrasive hose can be selected to transfer abrasive fluids. The peristaltic pump has multiple control modes, which facilitates the integration with the system control and completes the condensate drainage function in real time.

Good air tightness, preventing external air from entering the condenser through the drainage system

The peristaltic pump itself has good air tightness, no need to use the valve, no liquid return and siphon, even when the pump is not running, the hose will be well sealed due to extrusion.

The condensate can be drained timely and effectively

The peristaltic pump has a strong self-priming capacity up to 0.95Bar and is suitable for vacuum environments with a minimum pressure of -0.95Bar (g)

The peristaltic pump has a variety of drainage modes, the drainage flow of the peristaltic pump with fixed rotating speed is stable, and the adjustable speed peristaltic pump can change the drainage speed according to the actual water volume to realize the timely drainage function

The peristaltic pump has a variety of control modes. The running state of the pump is controlled through RS485 communication control, analog signal control, etc., which is convenient for system control integration and real-time condensate drainage function.

Suitable for discharging condensate containing solid particles

When the peristaltic pump transmits fluid, the fluid only contacts with the inner chamber of the hose, and the hose made of wear-resistant material can be used to transmit abrasive condensate for a long time.

Soft particle size<25% * ID

Hard grain size<5% * ID

Suitable for discharging corrosive condensate

When the peristaltic pump transports fluid, the fluid only contacts with the inner chamber of the hose. Select the hose of suitable corrosion-resistant material, which can be used to transfer the corrosive condensate for a long time.

Good fluid transmission reliability and simple maintenance

Peristaltic pumps deliver fluid without valves and seals and without pump damage due to dry operation

Easy and convenient replacement of peristaltic pump hose, low maintenance cost

Related Products >

-

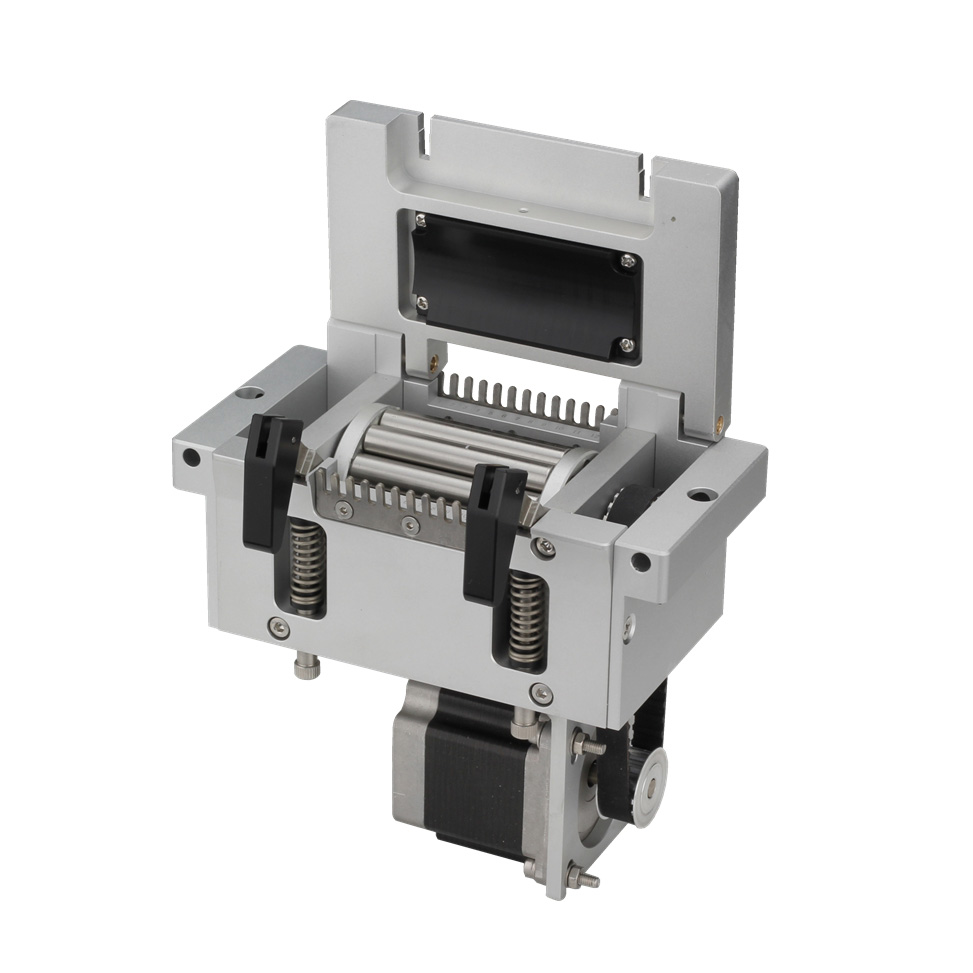

OEM-YG1212 Cap-pressing peri

The 12-channel integrated pressure block ,replace tubing easily and adjust flow conveniently. Solved the problem of excessive error between the channels of the

View product

-

WT600D High-flow constant-fe

Speed : 0.1-600 rpm,reversibleSpeed resolution : 0.1rpm(<100rpm), 1rpm(≥100rpm)Applicable pump heads : YZ1513、YZ2513、DMD1513、KZ25、YZ3513Flow rates : 0.0

View product

-

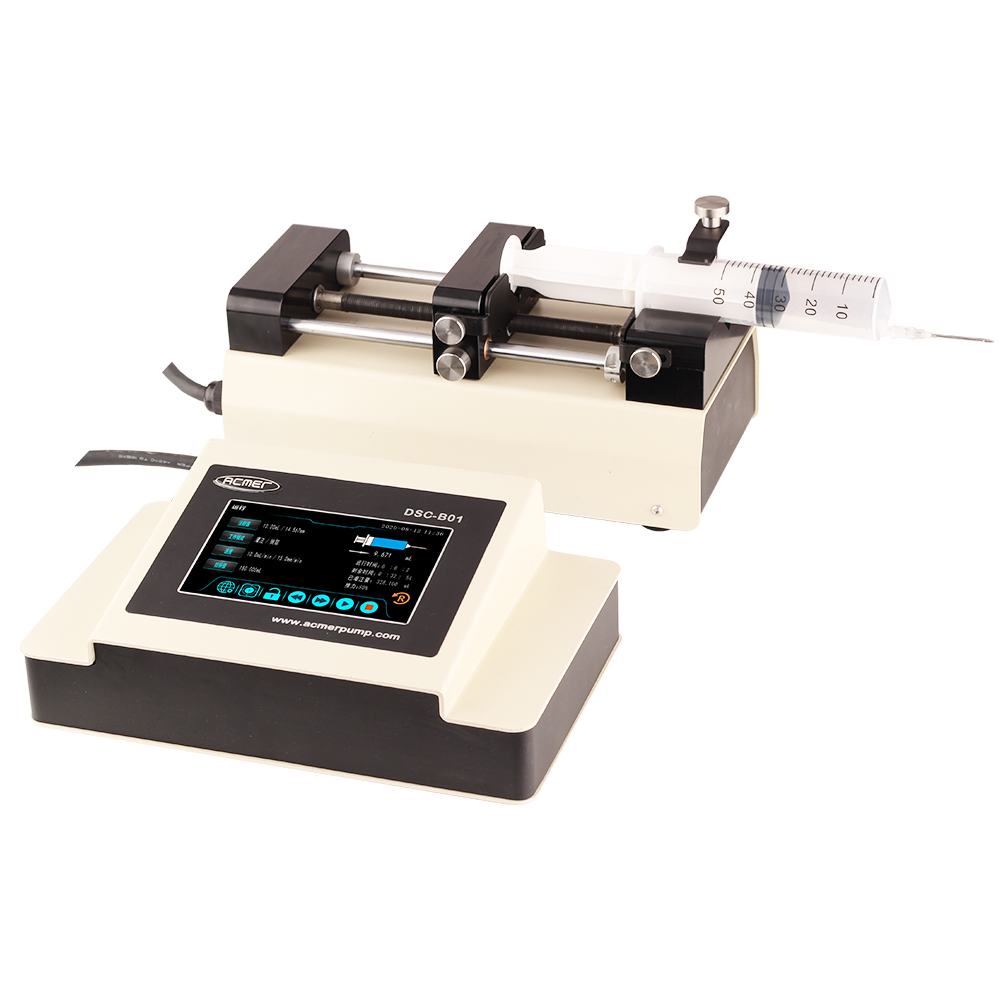

DSC-B01H2+W150-B01H2 High pr

Working Mode Infusion, Withdraw, Infusion / Withdraw, Withdraw / Infusion, Multipleinjection, Continuous No. of Syringes 1

View product

-

DSC-B01/W150-B01 Microfluidi

Working Mode Infusion, Withdraw, Infusion / Withdraw, Withdraw / Infusion, Multipleinjection, Continuous No. of Syringes 1

View product