Application of Laboratory Syringe Pump in High-pressure Electrostatic Spinning

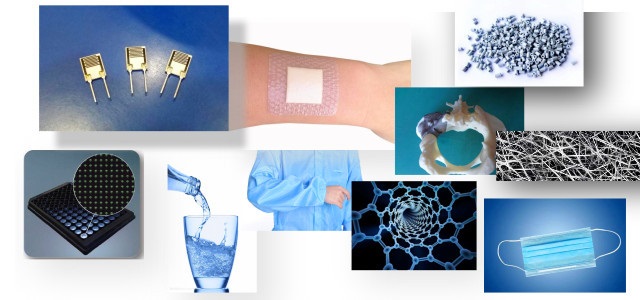

Electrospinning, i.e. the process of spinning with a polymer solution under high voltage static electricity. Electrospinning can prepare fibers with diameters of dozens to hundreds of nanometers. The products have high porosity and large specific surface area, diversified composition and uniform diameter distribution, and have very high application value in biomedical, environmental engineering and textile fields. Common electrospinned nanofibers can be used for water treatment, protective clothing, masks, etc. in filtration and personal protection; In the field of sensor, it can be used as a resistance sensor, an optical sensor, etc; In the chemical field, it can be used as catalyst, etc; In the biomedical field, it can be used for wound dressing, tissue engineering stent, drug carrier, etc.

High-pressure electrostatic spinning technology

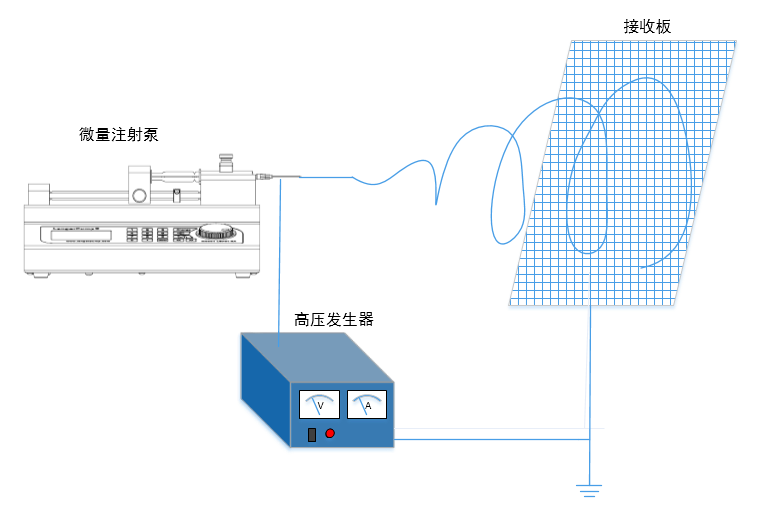

Electrospinning is a process for preparing polymer fibers by applying an applied electric field to a polymer solution under high voltage static electricity (thousands of volts to hundreds of thousands of volts). The fibers produced by electrostatic spinning are much finer than those produced by traditional spinning, with diameters ranging from dozens of nanometres to several microns, and the minimum diameter can reach 1nm.

In the process of electrostatic spinning, the spinning needle is generally connected to the high-voltage positive electrode, and the receiving plate or receiver kept a certain distance from the needle is connected to the negative electrode. Under the action of surface tension, the polymer solution appears as spherical droplets at the needle. With the increase of voltage, the surface charge density of the droplets increases. When the electrostatic force is greater than the surface tension, the droplets on the surface of the nozzle are elongated. When the critical voltage is reached, the liquid will change from spherical to cone-shaped, i.e. Taylor cone. As the voltage continues to increase, when the electrostatic force is greater than the equilibrium critical value, the liquid overcomes the tension on the outer surface of the spray head drop and moves toward the receiver. During the movement, the liquid accelerates, undergoes multiple tensile splitting, and finally forms nanofibers on the receiver.

Related Products >

-

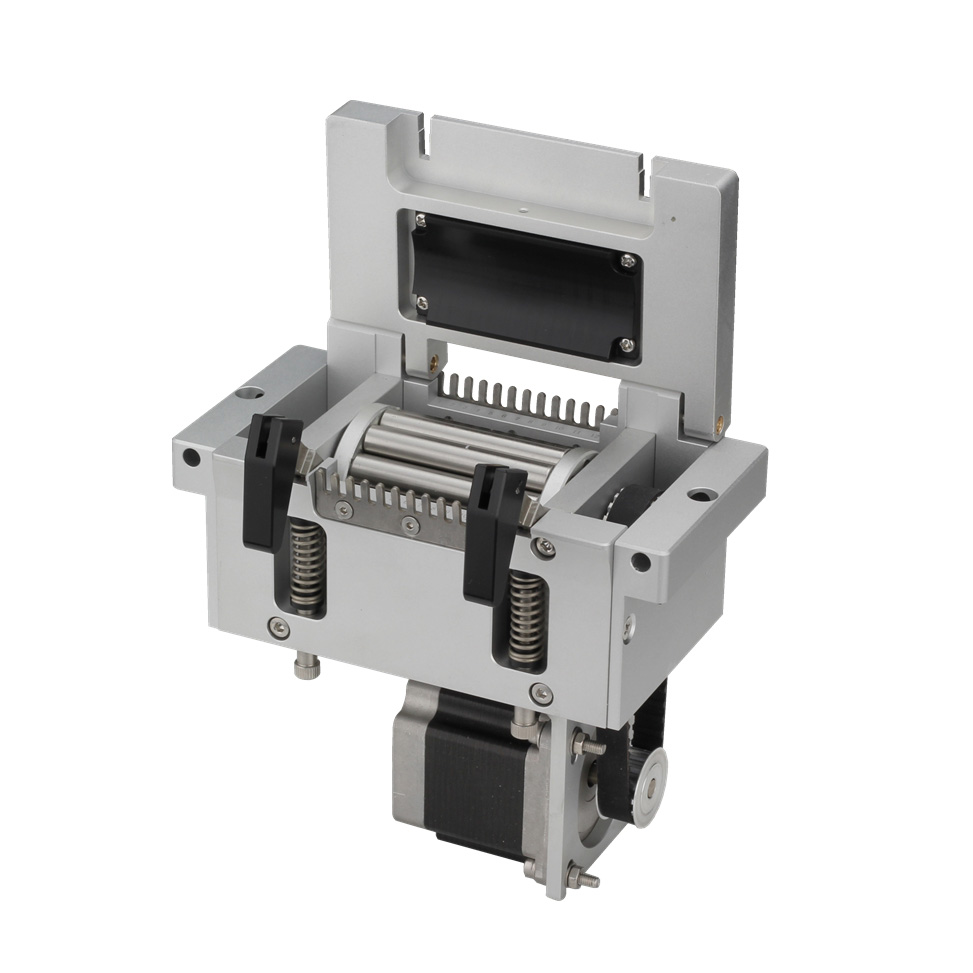

OEM-YG1212 Cap-pressing peri

The 12-channel integrated pressure block ,replace tubing easily and adjust flow conveniently. Solved the problem of excessive error between the channels of the

View product

-

WT600D High-flow constant-fe

Speed : 0.1-600 rpm,reversibleSpeed resolution : 0.1rpm(<100rpm), 1rpm(≥100rpm)Applicable pump heads : YZ1513、YZ2513、DMD1513、KZ25、YZ3513Flow rates : 0.0

View product

-

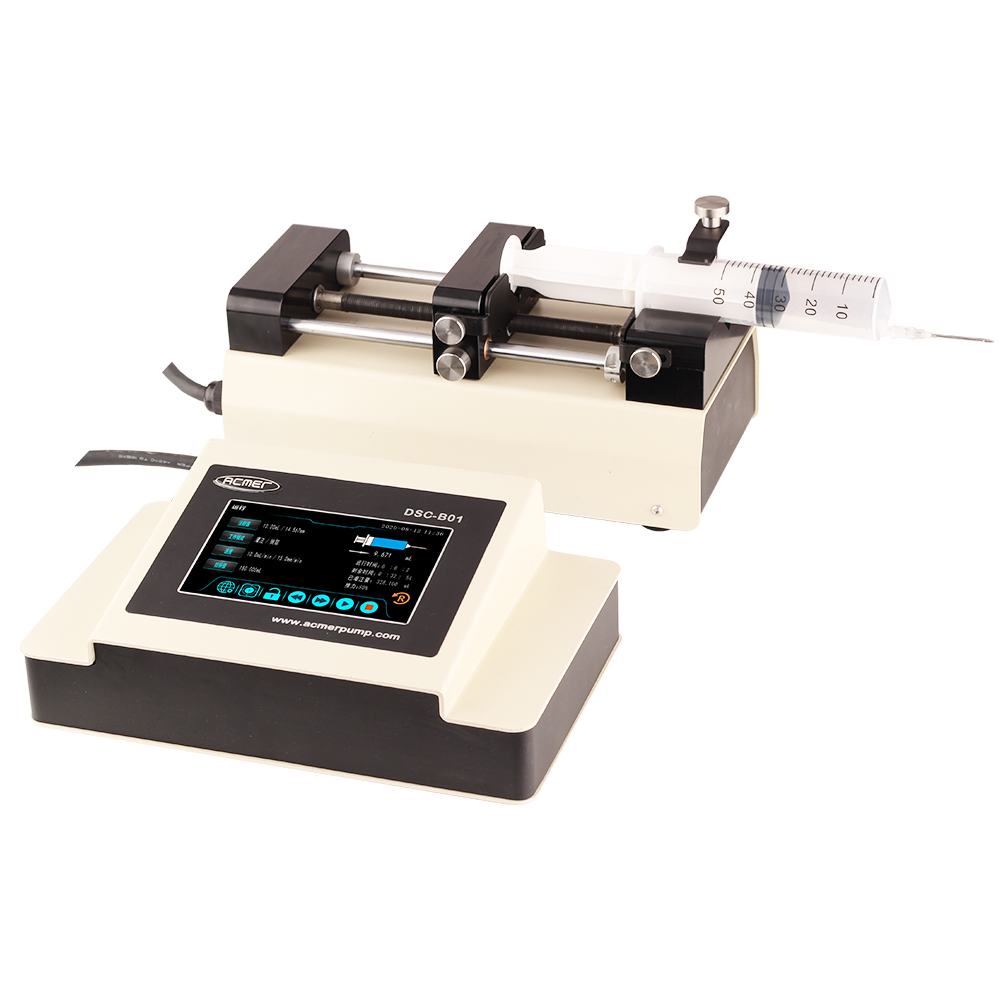

DSC-B01H2+W150-B01H2 High pr

Working Mode Infusion, Withdraw, Infusion / Withdraw, Withdraw / Infusion, Multipleinjection, Continuous No. of Syringes 1

View product

-

DSC-B01/W150-B01 Microfluidi

Working Mode Infusion, Withdraw, Infusion / Withdraw, Withdraw / Infusion, Multipleinjection, Continuous No. of Syringes 1

View product