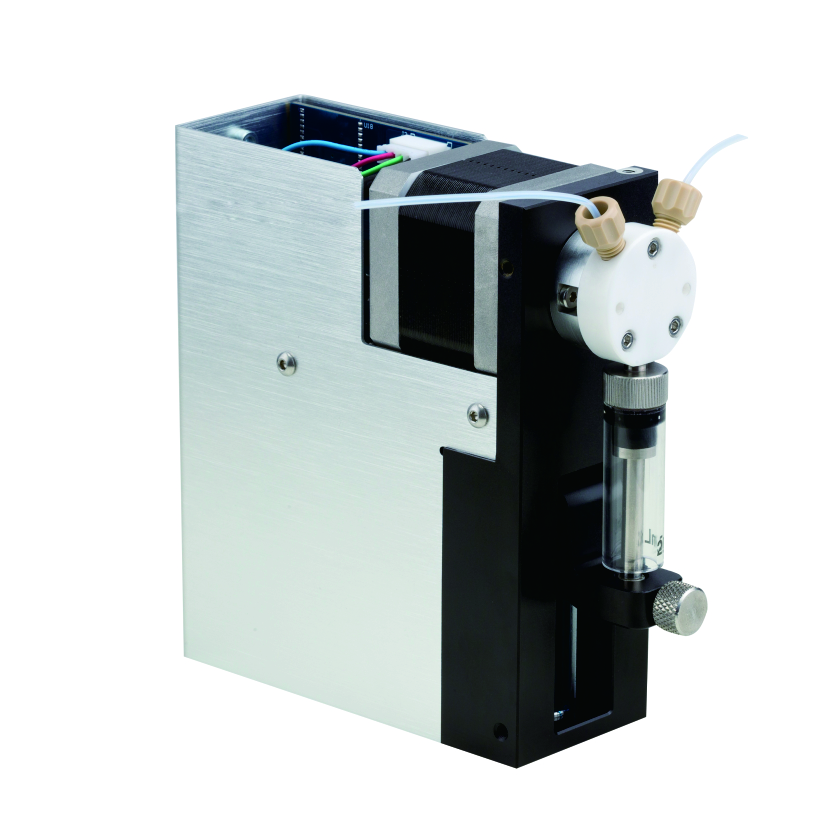

MSP30 Lab automation systems Syringe Pump

Stroke length:30mm

Flow rates:0.0025mL/min~250mL/min

Syringe:1

Display:-

Control:RS485/RS232/CAN

Linear Force:≥68N

- Product Specifications

- Help

- Service Guarantee

- Related Products

-

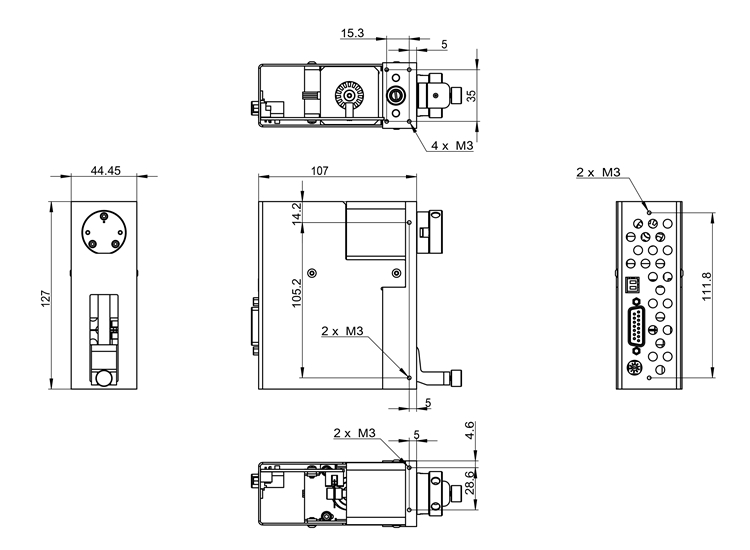

Technical Specifications Accuracy ≤1.0 % (syringe ≥1 mL) Precision CV≤0.05% at full stroke (with syringe ≥ 500 uL ) Wetted material Ceramics, borosilicate glass Dimension (L x W x H) 110mm*44.4mm*127mm Power supply DC 24V,1.5A (peak) Syringe and Drive Syringe fitting 1/4″-28 thread Syringe 50uL, 100uL, 250uL, 500uL, 1mL, 2.5mL, 5mL control resolution 0.01mm / 1 step; 0.625um / 1 step Travel 30mm/3000 steps or 48000 steps Time for full stroke 1.26s-1200s Drive system Ball screw drive Valve & Valve Drive Turn Time ≤250ms between adjacent ports Valve options 3-port distribution valve (Ceramic / PCTFE) Max pressure 0.5MPA Fitting 1/4″-28 thread Piston driving force ≥68N Secondary driving force of piston ≥34N Communication Signal input 2-channel TTL level signal input, used to control restart after pause command Signal output 3-channel TTL level signal output, used to indicate the working status Interface RS485 / 232, Automatic recognition Baud rate 9600bps or 38400bps Communication address 4-digit BCD dip switch, set 15 communication addresses Environmental Operating temperature Recommended: 15℃-40℃ ,use low temperature syringe for low temperature application Operating Humidity <80% RH, no condensation Storage temperature -20℃-65℃ Storage Humidity <80% RH, no condensation

-

How to select the type

Issues to be confirmed before type selection:

1. Determine the required flow rate (mL/min) and the number of channels required;

2. Determine use scenarios; Can be applied directly or used with equipment, supporting control via RS485 or external signals

3. parameter display; The digital tube only displays the rotational speed; LCD display of flow rate, rotational speed and other calibration parameters; The touchscreen displays flow, rpm, and other programmed or configured parameters

4. Liquid composition; Influence hose selection, platinum sulfide silica tubing is recommended for conventional fluids, and inlet hose is recommended for corrosive fluids

About drives

Flow - The higher the drive rpm, the greater the flow, selecting the appropriate driver by reference flow

Control mode - fixed speed; Adjustable speed; Speed adjustable, supporting flow correction (to achieve precise control of flow); Speed adjustable, support flow distribution (quantitative distribution); Multiple forms such as external signal control are available

Parameter display - digital tube, liquid-crystal display, touchscreen

Degree of protection - Requirements for the drive to be sealed, dustproof, and waterproof, depending on the environment of use

About Tubing

Platinum Vulcanized Silicon Rubber Tube – suitable for the transport of most conventional fluids

FWG60/FG60/A-60-F - Food grade, long life

IG60/A-60-G - Industrial grade, long life

PG60/pharmed BPT - Medical grade, long life

Chemical - Resistance to strong corrosive liquids, lined with Teflon coating

KG60/Viton - Strong corrosive resistant liquid, pure Teflon material

-

About the lead time

Peristaltic pump, injection pump, miniature piston pump, domestic silicon rubber tube and other series of products, most of which are off the shelf and can be shipped within 48 hours;

The filling machines, filling systems and other products are usually made to order, with relatively little inventory, a lead time of about 1 – 2 weeks, and a small number of off the shelf items;

Common models of imported hose series products are in stock; Due to the impact of international logistics on the imported hose, the lead time is about 1~4 weeks in special cases;

Remark: All peristaltic pump series products require 3 days of non-stop operation and aging before leaving the factory, to ensure a lower failure rate for customers to rest assured of use

About aftermarket

One year warranty (except consumables, improper use or man-made damage not covered by warranty)

Under special circumstances such as flow differences, service environment, personal reasons due to type selection or actual application, without affecting secondary sales, customer service exchanges may be contacted directly

About Logistics

In China, default Deppong/SF distribution, please communicate with customer service for special requirements and confirm